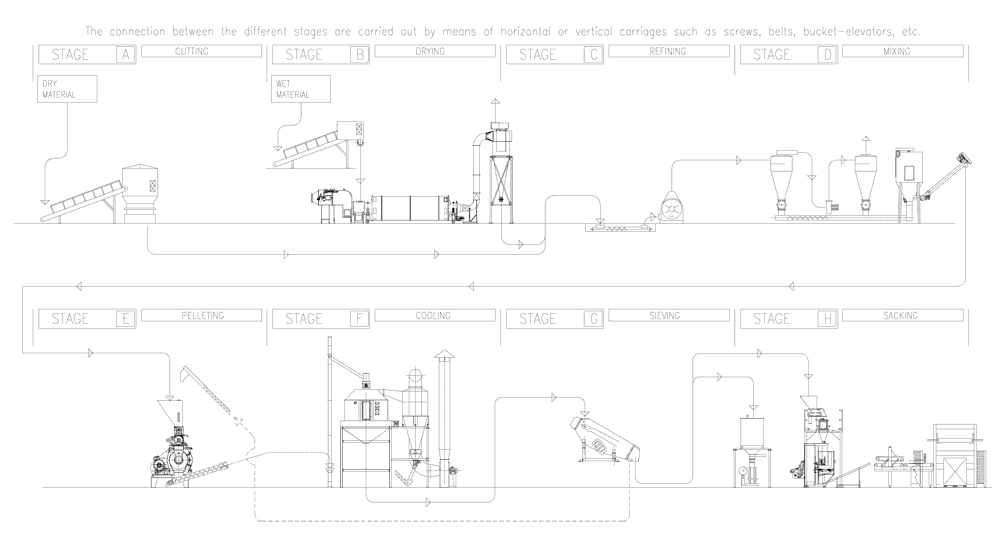

So a reduction in size is necessary. This operation can happen directly on the collection site, using specific machines with their own motors or connected to tractors. The product obtained is wet, has a medium size, named "chips", and is suitable to be transported using the most common transport systems. Now, the product must be dried to obtain the correct misture percentage for the inlet in pelleting machine.

The misture percentage of the wood must be reduced from 50% to not more than 12-13% through a rotary drum drier or a belt drier. This machines has a burner that can be feeded with oil, gasolina, gas or wood.

After been drier a refined, complete with sucking unit, reduces the dimensions of the product and prepares it for pelletizing. The product is also cleaned from any ferrous part or foreign matters.

A mixing silo make the product homogeneous and in this silo the product can be stocked.

In a conditioner, steam, molasses, fat or liquid can be added to the mixture bifore it enters the holes of the pellet-mill die, pressed by the rolls. On the outlet of the holes some knives cut the pellets at the desired lenght.

After pelleting, the product is very hot and a counterflow cooler cools it, to app +5°C above the environmental temperature, in order give it the right hardness and the better consistance to store and handle it. The machine is a counterflow cooler full line of air intake and recovery powders.

A sieve removes the fines form the pellets and a screw or pneumatic conveyor collect these fines and send them back to the pellet-mill.

The pelletized product is conveyed to the silo for stocking bifore delivery. It can be delivered in bulk, loaded on trucks and weighed through a weigh lorry or in bags. A manual or automatic weighing-sacking system and an eventual palletized are used for bagging the product.